Imagine having a year-round haven for your plants, protecting them from harsh weather conditions while providing the perfect growing environment. Well, look no further than a poly tunnel! This article will shed light on what a poly tunnel is and how it can revolutionize your gardening experience. With its versatile design and ability to extend the growing season, a poly tunnel is a valuable addition to any garden.

Definition of a Poly Tunnel

Basic description

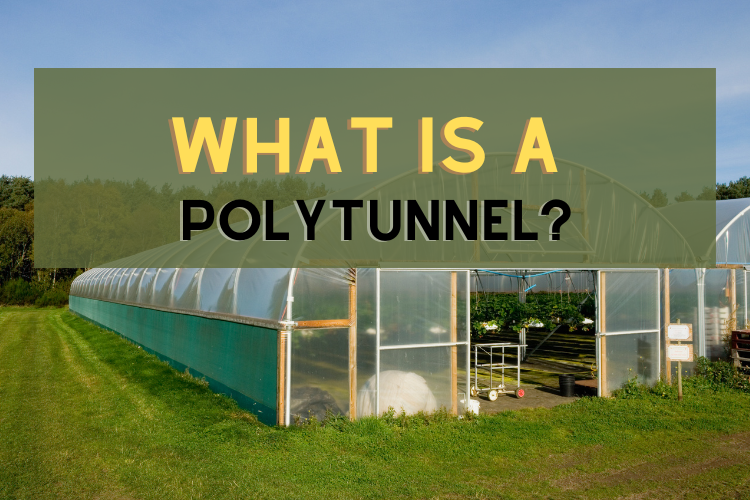

A poly tunnel, also known as a polyethylene tunnel or a hoop house, is a structure made of a flexible, translucent material stretched over a series of hoops or arches. It is commonly used in agriculture and gardening to create a protected growing environment for plants. The design of a poly tunnel allows for optimal control of the climate, extending the growing season and protecting crops from external elements, pests, and diseases. Whether you’re a farmer, a gardener, or a researcher, a poly tunnel can provide you with an ideal solution for cultivating plants in a controlled environment.

Composition and structure

The basic structure of a poly tunnel consists of a series of hoops or arches made of materials such as galvanized steel, wood, or PVC pipes. These hoops are anchored into the ground or a base frame, providing stability and support. The covering material, typically made of polyethylene plastic, is secured over the hoops, creating an enclosed space. Poly tunnels come in various sizes and shapes, ranging from small backyard structures to large-scale commercial installations.

Purpose and uses

Poly tunnels serve a variety of purposes and have numerous applications in agriculture, gardening, and research. They provide a controlled environment that protects plants from unfavorable weather conditions, such as heavy rain, strong winds, frost, and excessive heat. By maintaining optimal temperature and humidity levels, poly tunnels can extend the growing season, allowing for earlier planting and later harvesting. Additionally, poly tunnels offer protection against pests, birds, and other animals that can damage or consume crops. They are also cost-effective and scalable, making them a popular choice for small-scale growers as well as large agricultural operations.

Advantages of Using Poly Tunnels

Climate control

One of the major advantages of using poly tunnels is the ability to control the climate within the enclosed space. By manipulating factors such as temperature, humidity, and ventilation, you can create an optimal environment for plant growth. This is particularly beneficial in regions with extreme climates or unpredictable weather patterns. Poly tunnels can protect crops from frost, excessive heat, and strong winds, ensuring better yield and quality of produce.

Extended growing season

With a poly tunnel, you can significantly extend the growing season by providing plants with a controlled and protected environment. By starting seedlings earlier in the year and keeping them insulated from cold temperatures, you can achieve earlier harvests. Similarly, during the cooler months, a poly tunnel offers protection against frost, enabling you to continue growing crops that would otherwise be impossible. This extension of the growing season allows for a more diverse range of crops and increased productivity.

Protection from pests

Pests, birds, and other animals can wreak havoc on crops, causing damage and reducing yields. Poly tunnels act as a physical barrier, preventing pests from accessing your plants. The enclosed space also makes it easier to implement integrated pest management strategies, such as introducing beneficial insects or using organic pesticides, without harming the surrounding ecosystem. This protection from pests is particularly valuable for organic farmers who rely on natural methods of pest control.

Cost-effectiveness and scalability

Poly tunnels offer a cost-effective solution for growers of all scales. Compared to traditional permanent structures, such as greenhouses, poly tunnels are more affordable to construct and maintain. They require fewer materials and can be easily assembled and disassembled, making them portable and flexible. Additionally, poly tunnels can be scaled up or down to meet your specific needs. Whether you have a small backyard garden or a large commercial operation, poly tunnels offer a customizable and cost-effective solution.

Different Types of Poly Tunnels

There are several different types of poly tunnels, each with its own unique features and advantages. By understanding the different options available, you can choose a poly tunnel that best suits your specific needs and growing requirements.

Single-span poly tunnel

A single-span poly tunnel is the most basic type of poly tunnel and is often used for small-scale gardening or hobbyist purposes. It consists of a single arch or hoop that spans the entire length of the structure, providing a simple and compact growing area. Single-span poly tunnels are relatively easy to assemble and are ideal for individuals with limited space or budget constraints.

Multi-span poly tunnel

A multi-span poly tunnel consists of multiple arches or hoops joined together to create a wider and more spacious growing area. The hoops are spaced at regular intervals, with each section typically covered by a separate piece of polyethylene plastic. Multi-span poly tunnels offer increased capacity and versatility, allowing for the cultivation of a larger variety of crops. They are commonly used by commercial growers who require a larger growing space.

High-tunnel

As the name suggests, a high-tunnel poly tunnel is characterized by its increased height compared to other types of poly tunnels. This extra height provides ample vertical growing space and allows for the cultivation of tall crops or trellised plants. High-tunnel poly tunnels are particularly useful for vine crops, such as tomatoes, cucumbers, and grapes, as well as for vertical gardening techniques like hydroponics or vertical farming.

Low-tunnel

In contrast to high-tunnel poly tunnels, low-tunnel poly tunnels are designed with a lower height, typically less than waist height. They are often used for season extension and protection of crops during colder months. Low-tunnel poly tunnels are easy to construct and can be covered with a lightweight fabric or plastic material to protect plants from frost, wind, and pests. They are ideal for growing cold-hardy vegetables like lettuce, spinach, and kale.

Materials Used in Poly Tunnels

The choice of materials used in constructing a poly tunnel plays a crucial role in determining its durability, functionality, and overall performance. While there are various options available, certain materials are commonly used due to their specific properties and suitability for poly tunnel construction.

Polyethylene plastic

Polyethylene plastic is the most commonly used material for the covering of poly tunnels. It is chosen for its durability, flexibility, and excellent light transmission properties. Polyethylene plastic allows sunlight to penetrate while trapping heat inside the structure, creating a warm and favorable growing environment. It is available in different thicknesses, with thicker plastic offering increased longevity.

Galvanized steel

Galvanized steel is a popular choice for the framework of poly tunnels. It offers excellent strength and structural integrity, ensuring the stability of the structure even in harsh weather conditions. The galvanization process involves coating the steel with a layer of zinc, providing protection against corrosion and rust. This makes galvanized steel ideal for outdoor applications where exposure to moisture and other elements is unavoidable.

Wooden framework

For those looking for a more natural and aesthetically pleasing option, a wooden framework can be used in the construction of poly tunnels. Wood is readily available, easy to work with, and offers good insulation properties. It provides a rustic and organic look to the poly tunnel while maintaining structural integrity.

PVC (polyvinyl chloride) pipes are another commonly used material for constructing the framework of poly tunnels. They are lightweight, affordable, and easy to work with. PVC pipes are available in various sizes and can be easily bent to form the desired shape of the poly tunnel. However, it is important to note that PVC pipes may not be as durable as other materials and may degrade over time when exposed to sunlight.

Components of a Poly Tunnel

To understand the functioning and assembly of a poly tunnel, it is important to familiarize oneself with its various components. Each component plays a vital role in creating a stable and efficient growing environment for plants.

Frame

The frame of a poly tunnel provides the backbone and structure of the entire system. It is typically made up of arches or hoops that support the covering material. The frame can be constructed using materials such as galvanized steel, wooden beams, or PVC pipes, depending on the specific requirements and budget. The strength and stability of the frame are essential to withstand external factors such as wind, snow, and other loads that may be exerted on the structure.

Covering

The covering material is one of the most important components of a poly tunnel as it directly affects the climate and growing conditions within the structure. The covering can be made of polyethylene plastic, woven fabric, or glass, depending on the specific needs and preferences. It should be durable, UV resistant, and capable of allowing sunlight penetration while retaining and trapping heat inside the poly tunnel.

End walls

The end walls of a poly tunnel provide additional structural support and act as the entrance and exit points. They can be made of the same material as the frame or can be constructed using wooden panels or PVC sheets. The end walls also include doorways or openings to allow for easy access and ventilation. They should be designed in a way that ensures maximum weatherproofing and prevents heat loss.

Ventilation system

Maintaining adequate ventilation is crucial for controlling temperature, humidity, and air circulation within the poly tunnel. A ventilation system typically consists of vents or windows on the sides or roof of the structure. These vents can be manually operated or automated, allowing for the regulation of airflow based on the specific needs of the plants. Proper ventilation helps prevent the buildup of heat, humidity, and harmful gases, ensuring optimum plant growth and health.

Doors

Doors are an essential component of a poly tunnel as they provide access to the interior space and allow for easy movement of people and equipment. They can be simple hinged doors or sliding doors, depending on the specific design and requirements of the poly tunnel. Doors should be weatherproof, well-sealed, and durable to withstand frequent usage and external conditions.

Base and anchorage

A sturdy and well-prepared base is crucial for the stability of the poly tunnel. The base can be constructed using materials such as concrete, wood, or metal, depending on the location and specific requirements. Anchorage is equally important to secure the poly tunnel, especially in areas prone to high winds or other extreme weather conditions. Anchorage methods can include ground pegs, concrete footings, or anchor plates.

Setting Up a Poly Tunnel

Setting up a poly tunnel requires careful planning, preparation, and attention to detail. By following a systematic approach, you can ensure a successful installation and create an optimal growing environment for your plants.

Site selection

Choosing the right location for your poly tunnel is crucial for its overall performance and productivity. Consider factors such as sunlight exposure, access to water, proximity to power sources, and ease of transportation. Ideally, the location should receive maximum sunlight throughout the day and be free from obstructions such as trees or buildings that could cast shadows. Additionally, ensure that the site is well-drained and protected from excessive wind or other environmental disturbances.

Foundation preparation

Before assembling the frame of the poly tunnel, it is important to prepare a solid and level foundation. Depending on the type of base you choose, this may involve excavating the area, pouring a concrete foundation, or constructing a raised bed. The foundation should be sturdy enough to support the weight of the poly tunnel and provide stability against wind and other external forces.

Assembling the frame

Once the foundation is in place, you can begin assembling the frame of the poly tunnel. Follow the manufacturer’s instructions or consult a professional if necessary. Start by attaching the arches or hoops to the foundation, ensuring they are evenly spaced and properly aligned. Secure the hoops using appropriate fasteners or connectors, taking care to maintain the structural integrity of the frame.

Covering installation

After the frame is assembled, it is time to install the covering material. This typically involves stretching the polyethylene plastic or other chosen material over the frame and securing it in place. Ensure the covering is taut and free from wrinkles, as this will help maintain proper insulation and prevent damage caused by wind or snow buildup. Secure the covering using clips, bungee cords, or other fasteners recommended by the manufacturer.

Ventilation and door installation

Installing proper ventilation is essential for regulating temperature and humidity inside the poly tunnel. This includes installing vents or windows on the sides or roof of the structure. Follow the manufacturer instructions to ensure proper installation and operation of the ventilation system. Install doors at the desired locations, ensuring they are weatherproof and well-sealed. Consider the direction of prevailing winds and optimize the placement of vents and doors accordingly.

Securing the tunnel

To ensure the stability and longevity of the poly tunnel, it is important to secure it properly. This involves anchoring the structure to the ground or the foundation using appropriate methods such as ground pegs, concrete footings, or anchor plates. Regularly check and tighten any connections or fasteners to maintain the structural integrity of the poly tunnel. Additionally, consider implementing additional measures like windbreaks or shade cloth to protect the structure from extreme weather conditions.

Maintenance and Care

Proper maintenance and regular care are necessary to ensure the longevity and optimal performance of your poly tunnel. By implementing essential maintenance practices, you can prevent issues, mitigate risks, and maximize the productivity of your plants.

Cleaning and sanitizing

Regular cleaning and sanitizing of the poly tunnel are crucial to prevent the buildup of algae, molds, pests, and disease-causing pathogens. Remove any debris, fallen leaves, or plant residues that can harbor pests or provide a breeding ground for diseases. Use a mild detergent or disinfectant to clean the structure, ensuring all surfaces are thoroughly rinsed and dried before reintroducing plants.

Monitoring and adjusting climate

Consistent monitoring of the climate inside the poly tunnel is essential for maintaining optimal growing conditions. Use thermometers, hygrometers, and other appropriate monitoring devices to measure temperature, humidity, and light levels. Make necessary adjustments to ventilation, shading, or heating systems to ensure plants are not exposed to extreme conditions. Regularly check and calibrate any automated climate control devices to ensure accurate readings and functioning.

Regular inspection

Conduct regular inspections of the poly tunnel to identify any signs of wear and tear, such as loose connections, tears in the covering material, or damaged components. Address any issues promptly to prevent further damage or compromised growing conditions. Inspect the anchorage and foundation to ensure they remain secure and stable, especially after severe weather events.

Repairs and maintenance

Inevitably, repairs and maintenance will be required over time. Promptly address any damages or issues that arise, such as tears in the covering material, broken parts, or malfunctioning systems. Replace any damaged components or fasteners to maintain the structural integrity of the poly tunnel. Regularly lubricate moving parts, such as hinges and mechanisms, to prevent rust and ensure smooth operation.

Replacing covering material

The covering material of a poly tunnel may require replacement over time due to wear and tear or degradation caused by sunlight exposure. Monitor the condition of the covering material regularly and replace it when necessary. Consider upgrading to a higher-quality or UV-resistant material for increased longevity. Plan for covering replacements well in advance to minimize downtime and disruptions to plant growth.

Common Challenges and Solutions

While poly tunnels offer numerous advantages, they are not immune to challenges and potential issues. By being aware of common challenges and implementing appropriate solutions, you can mitigate risks and ensure the effective functioning of your poly tunnel.

Extreme weather conditions

Poly tunnels can be susceptible to damage from strong winds, heavy snowfall, or extreme temperature variations. To minimize the risk, regularly inspect the poly tunnel for signs of damage or weakness and reinforce any vulnerable areas. Implement windbreaks or shade cloth to protect the structure from excessive wind or heat. Consider additional measures such as snow removal or insulation during colder months to prevent snow accumulation or heat loss.

Pest and disease management

While poly tunnels offer protection against pests, they can still be susceptible to infestations and diseases. Implement integrated pest management strategies, such as regular scouting, introducing beneficial insects, or using organic pesticides when necessary. Practice crop rotation to minimize the buildup of pests and diseases. Regularly sanitize the poly tunnel to prevent the spread of pathogens or fungal spores.

Structural integrity

Over time, the structural integrity of a poly tunnel may be compromised due to wear and tear, corrosion, or shifting of the foundation. Regularly inspect the frame, foundation, and connections to identify any signs of weakness or damage. Reinforce or replace any damaged components to ensure the stability and longevity of the structure. Additionally, consider reinforcing the anchorage or foundation in areas prone to high winds or other external forces.

Condensation and humidity control

Condensation and excessive humidity within the poly tunnel can lead to plant diseases and detrimental effects on growth. Proper ventilation and a well-designed airflow system are key to managing condensation and humidity levels. Optimize the placement and operation of vents or windows to create a balanced airflow that allows for proper air circulation and reduces moisture buildup. Use dehumidifiers or fans if necessary to control humidity levels during periods of high moisture.

Examples of Successful Poly Tunnel Applications

Poly tunnels have proven to be versatile and effective in a wide range of applications. Here are some examples of how poly tunnels have been successfully utilized:

Commercial agriculture

Commercial farmers have embraced poly tunnels as a cost-effective and efficient method of increasing productivity and diversifying crop options. From small-scale organic farms to large-scale vegetable production operations, poly tunnels offer the ability to extend the growing season, protect crops from pests and adverse weather conditions, and optimize resource utilization.

Home gardening

Poly tunnels have become popular among home gardeners and hobbyists, allowing them to grow a wider variety of plants and extend the growing season in regions with shorter summers. Home gardeners can enjoy fresh produce year-round, experiment with different crops, and protect delicate plants from harsh environmental factors.

Nurseries and seedling propagation

Poly tunnels provide an ideal environment for nurturing seedlings and propagating young plants. The controlled climate, protection from pests, and enhanced growth conditions make poly tunnels the perfect setting for nurseries and greenhouse operators. By starting seedlings in a poly tunnel, growers can ensure healthy and vigorous plants ready for transplanting.

Research and experimentation

Poly tunnels serve as valuable research tools for agricultural institutes and universities. Researchers can create controlled environments to study the effects of various climate variables on plant growth and development. Poly tunnels enable the replication of specific conditions, allowing for precise experimentation and data collection.

Organic farming

Organic farmers rely on natural and sustainable practices to grow crops without the use of synthetic pesticides or fertilizers. Poly tunnels offer a physical barrier against pests, reducing the need for chemical control methods. Organic farmers can use integrated pest management strategies, such as introducing beneficial insects and implementing biological control measures, more effectively within the controlled environment of a poly tunnel.

Conclusion

Poly tunnels provide a valuable solution for growers of all scales and purposes. The ability to create a controlled and protected environment for plants offers numerous advantages, including climate control, extended growing seasons, pest protection, and cost-effectiveness. By choosing the right type of poly tunnel, using suitable materials, and implementing proper maintenance and care, you can create an optimal growing environment and enhance the productivity and success of your agricultural or gardening endeavors. Whether you are a commercial farmer, a home gardener, or a researcher, incorporating a poly tunnel into your growing practices can significantly contribute to your success and enjoyment of plant cultivation.